DTF (Direct-to-Film) printing has revolutionized film transfer processes, offering fast, precise, and high-quality results on diverse materials for industries like signage and automotive. It streamlines production, reduces costs, and increases profit margins for printing service providers, while providing clients with vibrant, long-lasting prints. The process involves selecting films and inks, efficient inventory management, quality control, and direct delivery to service providers. Choosing the right supplier is crucial, focusing on specialists with a strong reputation, consistent quality, and timely delivery. DTF's popularity grows due to its cost-effectiveness, high-quality results, and environmental benefits, staying competitive in dynamic markets and meeting consumer expectations. Case studies demonstrate successful adoption in various sectors, enhancing operational efficiency and customer satisfaction.

“Unleash the potential of direct-to-film (DTF) printing with wholesale transfers, a game-changer for printing service providers. This innovative technology is transforming the industry, offering unparalleled efficiency and quality. In this comprehensive guide, we explore the benefits, process, and market trends surrounding DTF Printing. From understanding its revolutionizing impact to choosing the perfect supplier, we provide insights for service providers seeking to thrive in today’s competitive landscape. Discover how DTF transfers are enhancing productivity and customer satisfaction.”

- Understanding DTF Printing: A Revolution in Film Transfer

- Benefits of Wholesale Direct-to-Film Transfers for Service Providers

- The Process: From Bulk Purchasing to Print Delivery

- Choosing the Right Supplier for High-Quality Results

- Market Trends and Demand for DTF Printing Services

- Case Studies: Successful Implementation and Customer Satisfaction

Understanding DTF Printing: A Revolution in Film Transfer

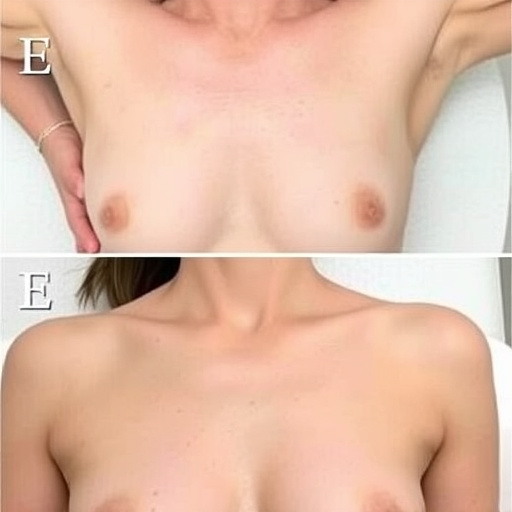

Direct-to-film (DTF) printing has revolutionized the way we approach film transfers, offering a sleek and efficient alternative to traditional methods. This cutting-edge technology allows for precise, high-quality prints directly onto various media, including metal, plastic, and even glass. By eliminating the need for intermediate steps, DTF Printing streamlines production processes, making it an attractive option for printing service providers.

With its ability to produce vibrant, long-lasting images, DTF Printing has become a game-changer in industries ranging from signage to automotive, offering unparalleled versatility and customization. The direct application of ink onto the desired surface ensures consistent results, enabling businesses to deliver exceptional products that cater to modern demands.

Benefits of Wholesale Direct-to-Film Transfers for Service Providers

Wholesale direct-to-film (DTF) transfers offer a range of advantages for printing service providers, streamlining their operations and enhancing their competitive edge. By cutting out intermediaries, DTF printing allows businesses to acquire high-quality film transfers at lower costs, improving profit margins significantly. This cost-effectiveness is passed on to clients, making it an attractive option for service providers aiming to remain competitive in the market.

Moreover, DTF transfers provide a faster and more efficient printing process. With direct application of ink onto film, the need for intricate intermediate steps is eliminated, reducing production time. This efficiency means service providers can take on more projects without compromising quality or speed, enabling them to meet client demands promptly and effectively.

The Process: From Bulk Purchasing to Print Delivery

The process of wholesale direct-to-film (DTF) transfers for printing service providers involves several streamlined steps, ensuring a seamless experience from bulk purchasing to final print delivery. It begins with service providers selecting from a vast array of films and inks offered by wholesalers, catering to diverse customer preferences and print requirements. This initial phase is key in setting the foundation for high-quality outcomes.

Once orders are placed, the DTF transfer process kicks into gear. Wholesalers meticulously manage inventory, ensuring bulk materials are readily available for efficient production. Film cutting and printing occur in specialized facilities, utilizing advanced machinery to achieve precise, vibrant results. After printing, the films undergo quality control checks to maintain consistency and meet strict standards. Finally, the prepared films are packaged and delivered directly to the service provider, ready for integration into their print workflows, thus enabling them to offer top-tier DTF printing services to their clients.

Choosing the Right Supplier for High-Quality Results

Selecting the ideal supplier is paramount when offering high-quality DTF (Direct-to-Film) printing services. It’s a crucial step to ensure your clients receive exceptional results and are satisfied with your work. Look for suppliers who specialize in DTF Printing, as they will have the expertise and equipment needed to handle intricate details and diverse print requirements.

Reputation and experience are key indicators. Choose a supplier with a proven track record of delivering consistent quality and meeting deadlines. Reviews from previous clients can provide valuable insights into their performance and customer service. Additionally, consider their capacity to accommodate your volume needs, ensuring they can handle large orders without compromising on output or quality.

Market Trends and Demand for DTF Printing Services

The demand for direct-to-film (DTF) printing services has been on a steady rise, driven by several market trends in the print and packaging industry. With the surge in custom printing requests, service providers are increasingly looking for efficient and cost-effective solutions to meet customer expectations. DTF Printing offers a unique advantage by enabling high-quality printing directly onto various film materials without intermediate plates, making it an attractive option for short-run, on-demand productions.

Moreover, the growing popularity of eco-friendly packaging and sustainable practices has further fueled the demand for DTF Printing. This method reduces waste by eliminating the need for plate preparation and allows for more flexible design iterations, catering to the dynamic nature of modern markets. As consumers become more conscious of environmental impacts, printing service providers are embracing DTF as a responsible alternative, ensuring they stay competitive in a rapidly evolving industry landscape.

Case Studies: Successful Implementation and Customer Satisfaction

Direct-to-film (DTF) printing has been a game-changer for many printing service providers, offering an efficient and cost-effective solution for large-scale projects. Case studies from various industries showcase the successful implementation of DTF technology, highlighting its ability to meet the demands of modern printing needs.

One notable example involves a graphic design studio specializing in outdoor advertising. By adopting DTF Printing, they streamlined their production process, reducing time and labor costs significantly. The studio’s clients, including multiple national brands, reported exceptional print quality and timely deliveries, leading to increased customer satisfaction and loyalty. This case study underscores the effectiveness of DTF printing in enhancing operational efficiency and delivering superior results for both service providers and end-users.